Automatic Chip Characters Recognition System

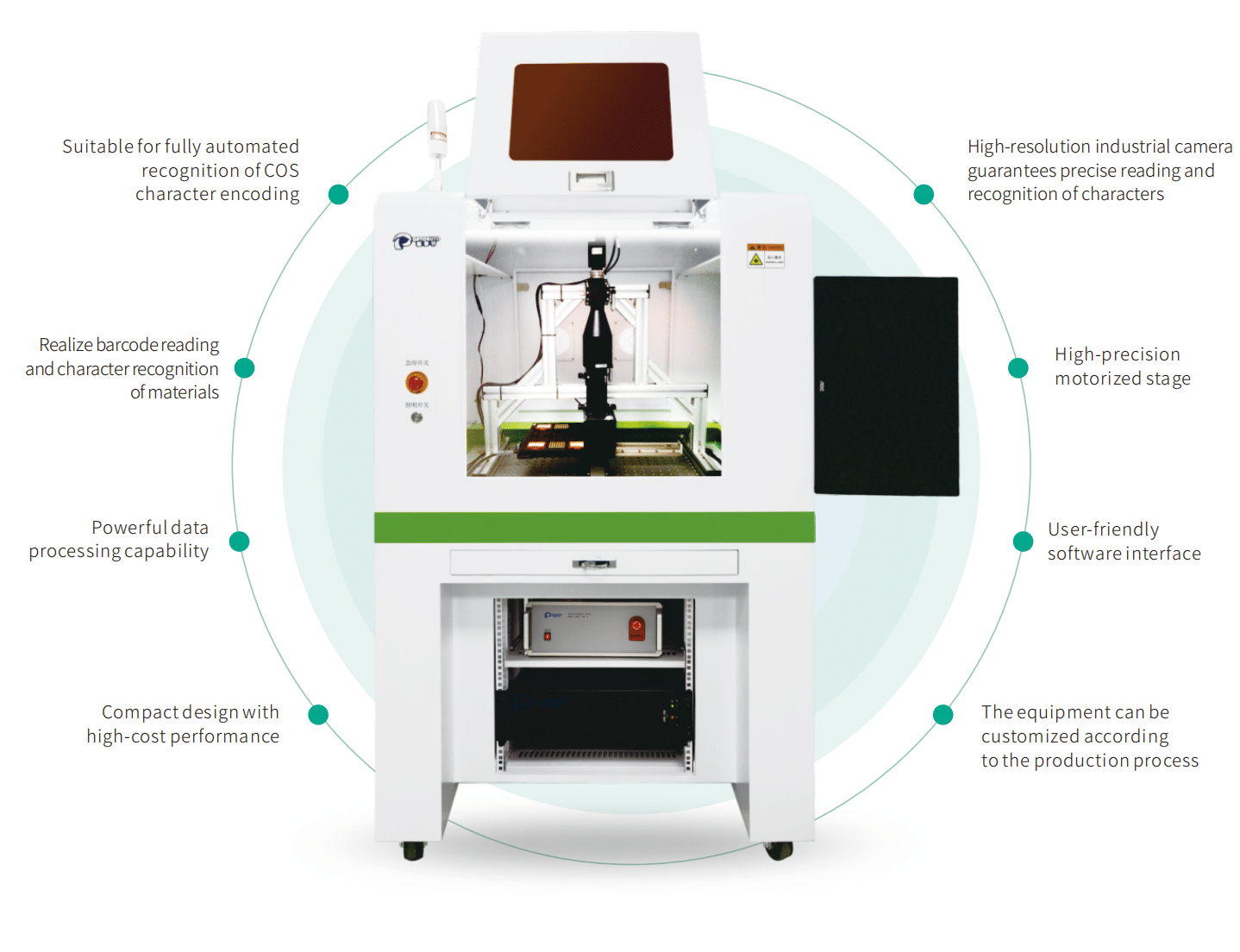

Our company’s independently developed Automatic Chip Characters Recognition System (Model: OA2000-COSOCR) is designed for the automatic recognition of COS character encoding. The system is equipped with a motor and motor structure to efficiently position and recognize materials, and utilizes a high-precision stainless steel automatic sliding table to ensure precise movement in three-dimensional space. We offer an intelligent controller along with the proprietary operating software developed independently by our company. The COS character recognition system can significantly improve efficiency and reduce reliance on skilled operators, with the added benefit of reducing recognition errors, when compared with manual recognition.

The system consists of a machine vision unit, motor control unit, and programmable control software. The core motor control unit uses highly precise and durable motors imported from Japan, ensuring long-term stable operation. The combination of efficient and accurate character recognition algorithms with our unique control technology guarantees comprehensive machine performance, achieving fully automated character encoding recognition.

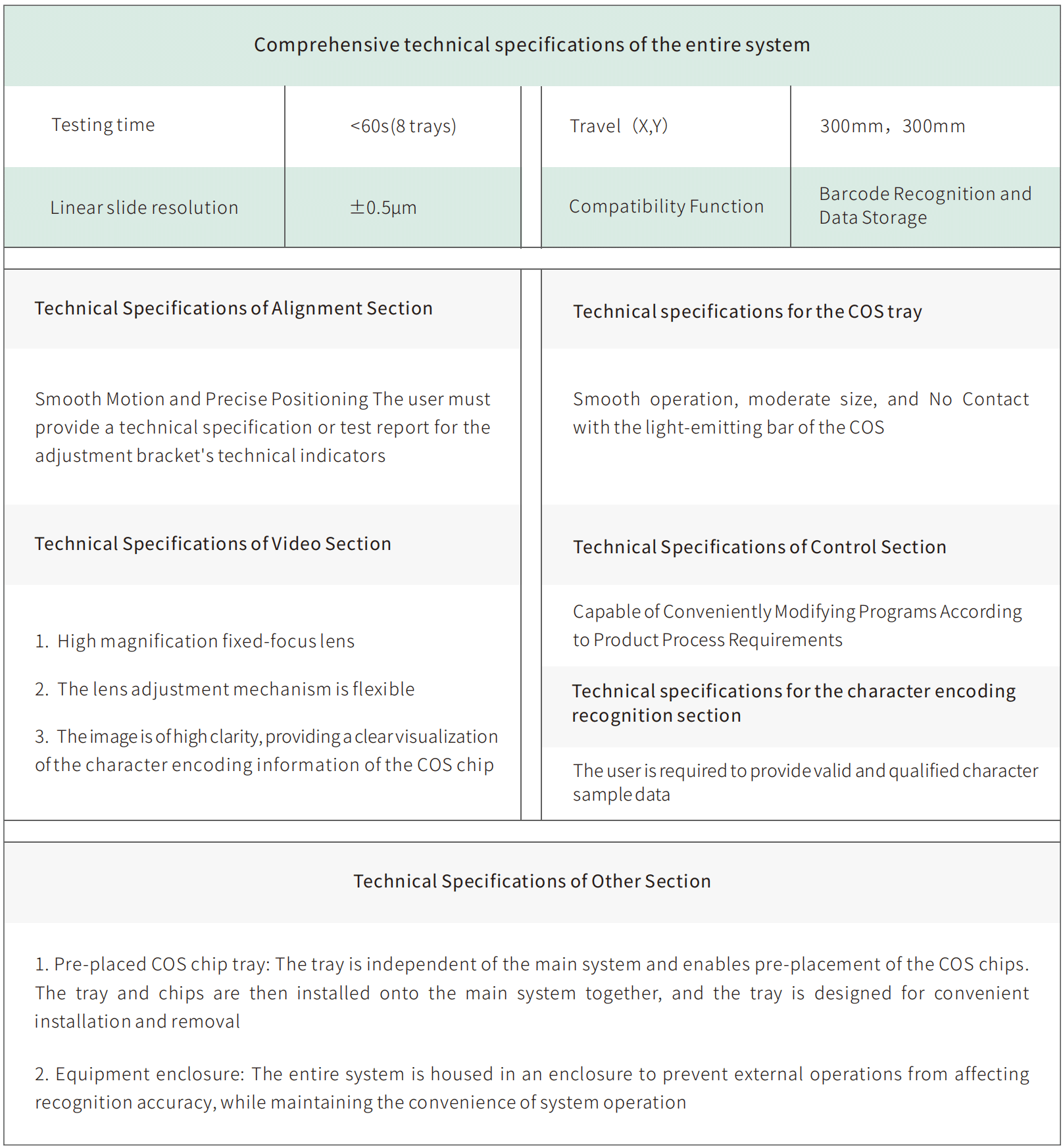

Test Time (8 trays)

| Name | Automatic Chip Characters Recognition System |

| Model | OA2000-COSOCR |

| Pressure range | 0.6 ± 0.1 MPa |

| Rated voltage | 220V / 16A |

| Power supply | (198~242) VAC,50Hz |

| Vacuum source | -0.07Mpa |

| Network | Cat5/6 |

| Outline dimension | W800xD1000xH1685mm (excluding the expanded portion of the observation window and the display) |

| Weight | 190kg |

| Operating environment | Avoid high temperatures and ensure good lighting in the working area Do not expose the equipment to moisture and do not use it in workshops without adequate rain protection measures For indoor use only |

| Equipment structural requirements | The equipment’s structural layout should be reasonable, with no interference between modules, and with sufficient clearance |

| Other requirements | ① The equipment’s design and manufacturing should feature advanced mechanical structure, process manufacturing, control systems, and user-friendly design, while ensuring safe operation ② The necessary standard configuration for the equipment’s normal use must be complete and matching, including all corresponding accessories, cables, tools, and spare parts |

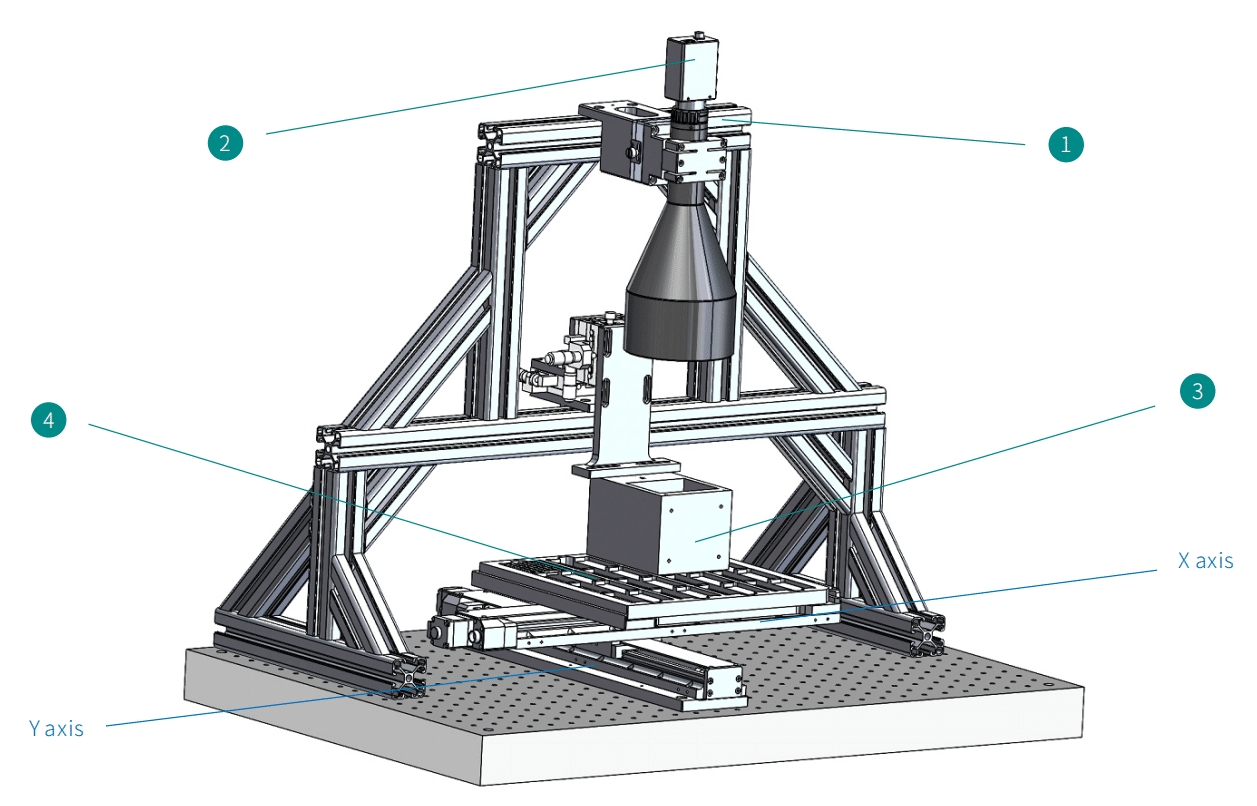

| S/N | Name | Remarks |

| 1 | Aluminum Profile Frame | Adjustable module position with horizontal movement capability |

| 2 | Industrial camera | Collaborating with light sources to obtain clear images without motion blur in dynamic environments |

| 3 | Coaxial light source | Enhancing image clarity |

| 4 | Material tray | Capable of accommodating up to 9 customer trays |

| 7 | X axis | Travel: 300mm |

| 8 | Y axis | Travel: 300mm |