High-speed Automatic SAC Assembly System

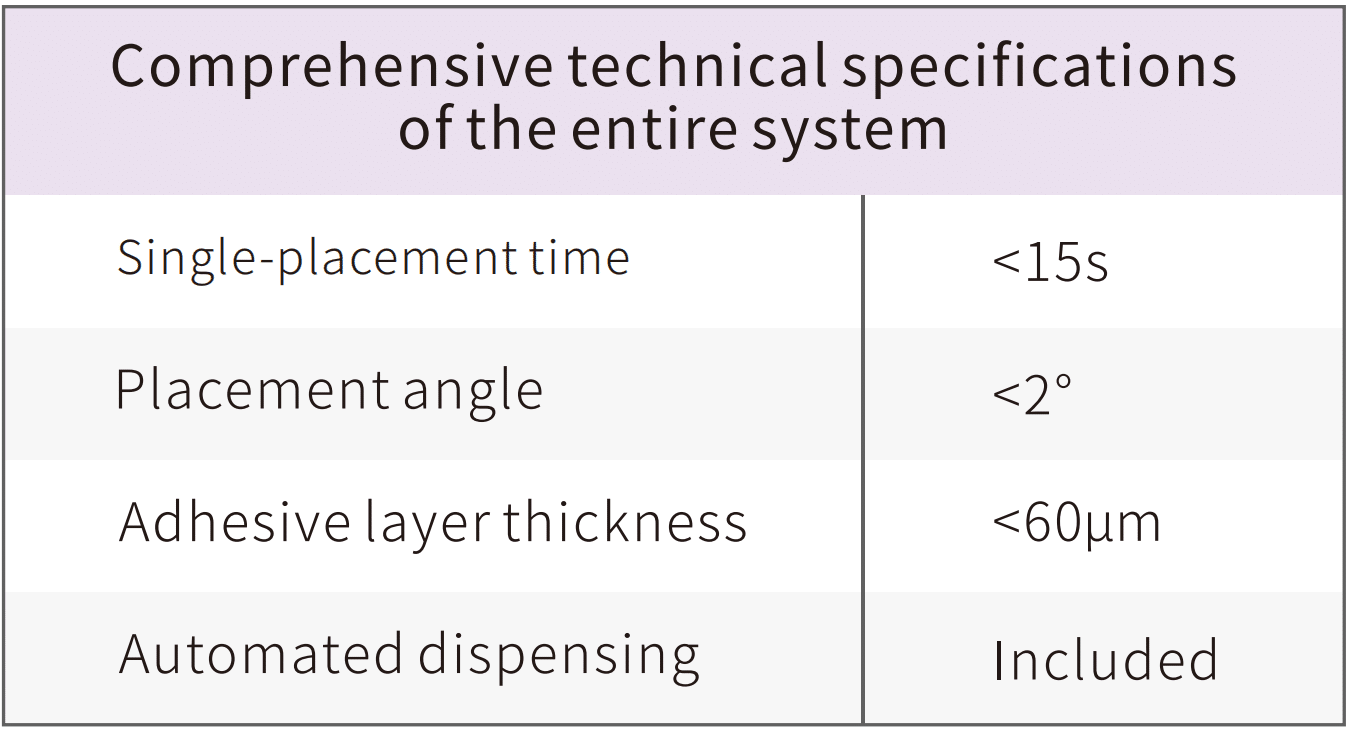

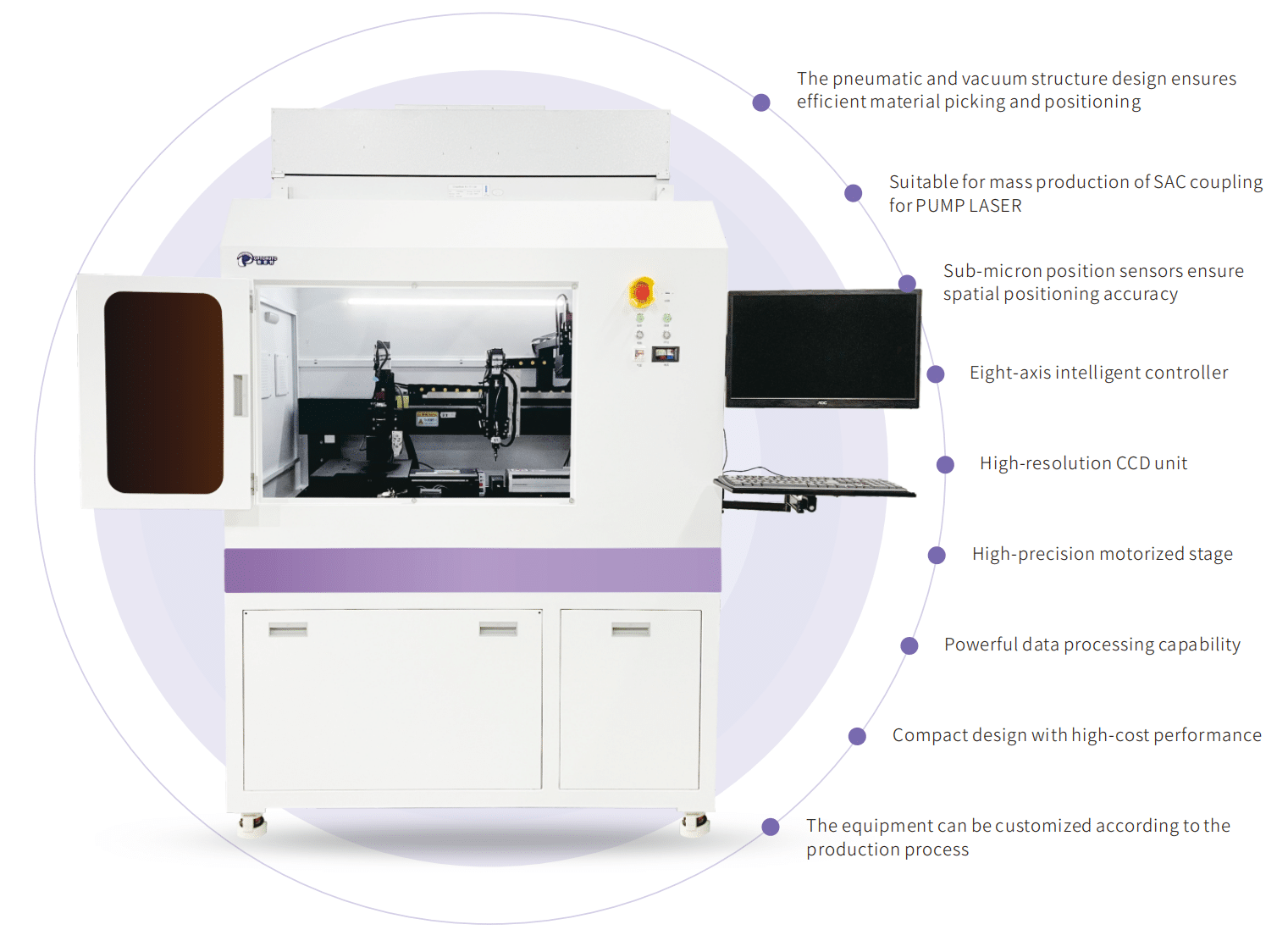

Our company’s independently developed High-speed Automatic SAC Assembly System(Model: OA8000-PLS) is designed for the automated production process of coupling SACs for array semiconductor pump lasers, allowing for fully automatic SAC assembly. The system’s key features include automatic material feeding, automatic dispensing, automatic data storage, automatic data uploading to customer databases, automatic alarms and etc.

The system is compatible with multiple control cards and uses customized image acquisition modules, which can simultaneously assemble multiple materials and quickly complete the coupling of multiple light paths. Compared with traditional manual bonding processes, the system has higher product accuracy and controllable consistency.

| Name | High-speed Automatic SAC Assembly System |

| Model | OA8000-PLS |

| Positive pressure source | 5.0kg / cm2 |

| Negative pressure source | 0.8kg / cm2 |

| Rated voltage | 200-240V / 10A |

| Rated Power | 1.8 KW |

| Power supply / Frequency | AC220 Voltage 50/60Hz / 4A (Normal) |

| Network | Cat5/6 |

| Outline dimension | W1400xD850xH2050mm (excluding the expanded portion of the observation window and the display) |

| Weight | 550kg |

| Operating environment | Avoid high temperatures and ensure good lighting in the working area Do not expose the equipment to moisture and do not use it in workshops without adequate rain protection measures For indoor use only |

| Equipment structural requirements | The equipment’s structural layout should be reasonable, with no interference between modules, and with sufficient clearance |

| Other requirements | ① The equipment’s design and manufacturing should feature advanced mechanical structure, process manufacturing, control systems, and user-friendly design, while ensuring safe operation ② The necessary standard configuration for the equipment’s normal use must be complete and matching, including all corresponding accessories, cables, tools, and spare parts |

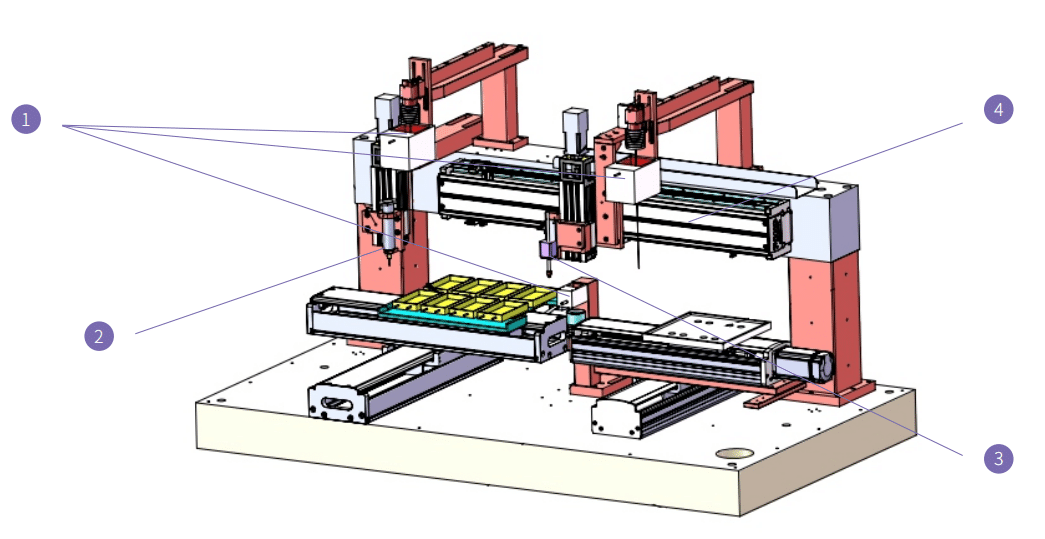

| S/N | Name | Remarks |

| 1 | CCD Camera | High-precision positioning for materials |

| 2 | Automatic dispensing device | Used for adhesive dispensing on materials |

| 3 | Material handling fixture | SAC suction |

| 4 | Mobile motor | Used for material handling and positioning |