Automatic Blue-laser FAC Alignment System

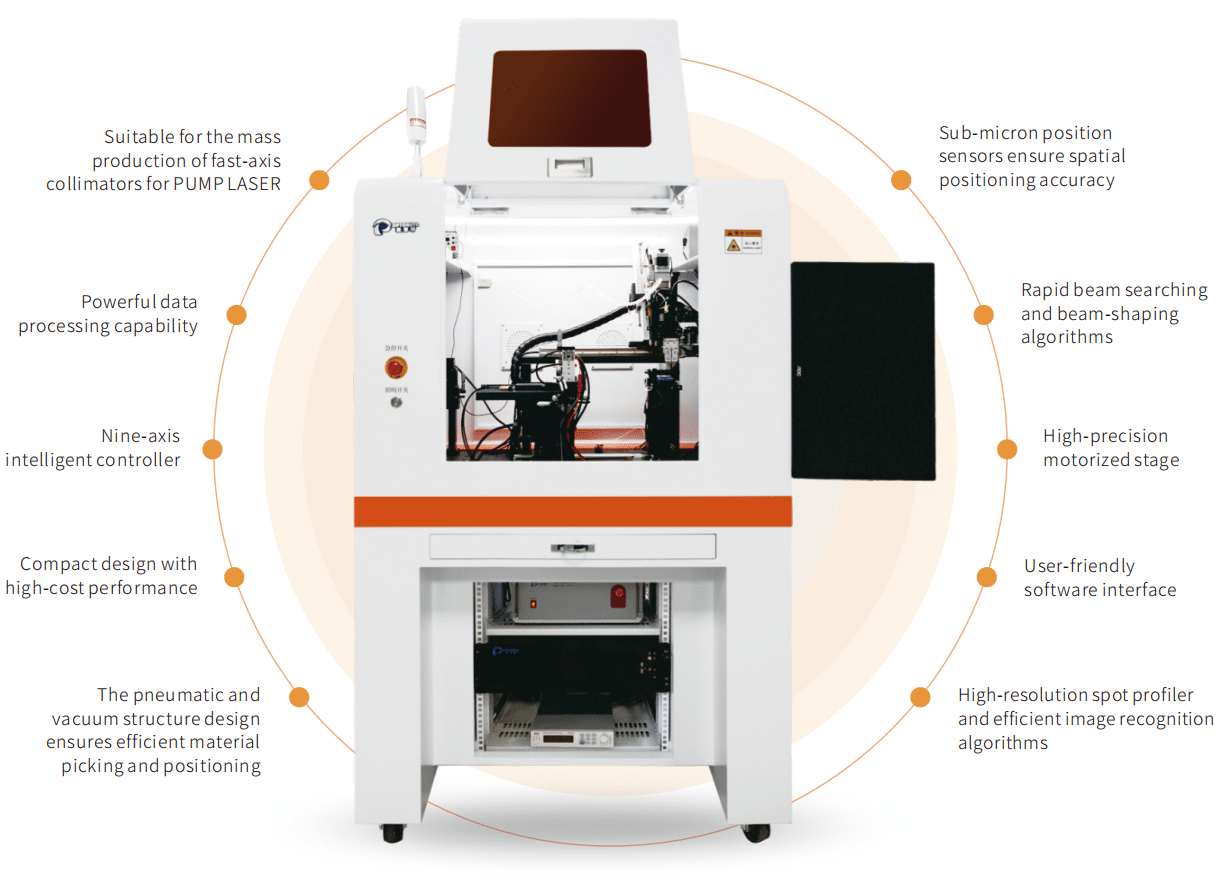

Our company’s independently developed Automatic Blue-laser FAC Alignment System(Model: OA9000-PBF) is designed for the automated production of array semiconductor fiber-coupled pump lasers. The system automates collimator mirror assembly, replacing the traditional manual production mode, which is still prevalent in the industry, leading to a significant increase in production efficiency while ensuring consistency in product specifications. The small size and ultra-short micrometer-level back focal length of the Fast Axis Collimator (FAC) collimator mirror make manual assembly extremely challenging and increase the likelihood of semiconductor chip damage. Our automation system provides an optimal solution to this practical problem.

This system comprises a motion unit, automatic dispensing unit, imaging unit, control unit, and programmable control software. The core motion unit features Japanese imported motors with high accuracy and long service life, ensuring long-term stable operation of the system. The combination of efficient image algorithms, our unique control technology, and dispensing design ensures that the system’s comprehensive performance is comparable to that of imported equipment from abroad.

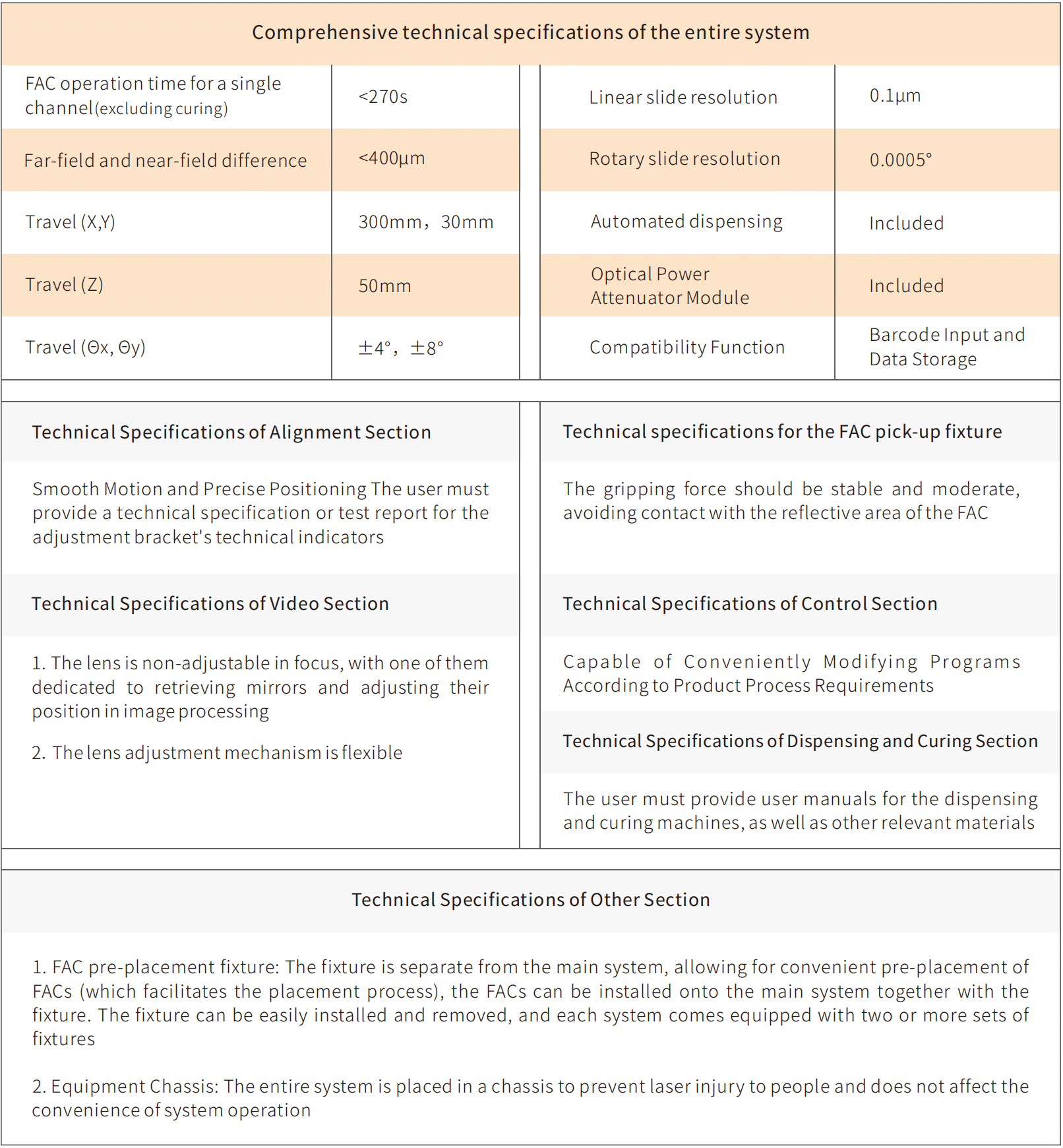

FAC operation time for a single channel (excluding curing)

Far-field and near-field difference

Linear slide resolution

Rotary slide resolution

| Name | Automatic Blue-laser FAC Alignment System |

| Model | OA9000-PBF |

| Pressure range | 0.6 ± 0.1 MPa |

| Rated voltage | 220V / 16A |

| Rated Power | 1.8 KW |

| Power supply | (198~242) VAC,50Hz |

| Vacuum source | -0.07Mpa |

| Network | Cat5/6 |

| Outline dimension | W800xD1000xH1685mm (excluding the expanded portion of the observation window and the display) |

| Weight | 300kg |

| Operating environment | Avoid high temperatures and ensure good lighting in the working area Do not expose the equipment to moisture and do not use it in workshops without adequate rain protection measures For indoor use only |

| Equipment structural requirements | The equipment’s structural layout should be reasonable, with no interference between modules, and with sufficient clearance |

| Other requirements | ① The equipment’s design and manufacturing should feature advanced mechanical structure, process manufacturing, control systems, and user-friendly design, while ensuring safe operation ② The necessary standard configuration for the equipment’s normal use must be complete and matching, including all corresponding accessories, cables, tools, and spare parts |

| S/N | Name | Remarks |

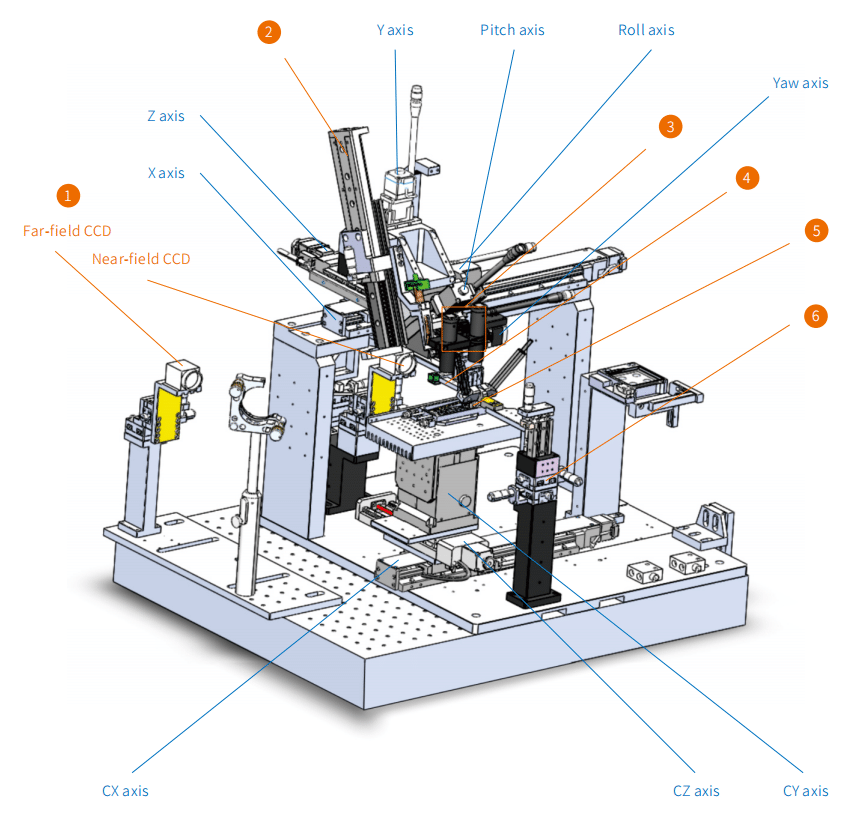

| 1 | Far/Near-field CCD | By precisely calibrating double CCDs to recognize the spot, the system accurately identifies the optimal location of the light and uses it to cure the adhesive at the FAC with precision and efficiency |

| 2 | Dispensing cylinder | The precise dispensing process is carried out smoothly with the help of the Japanese SMC pneumatic slide table |

| 3 | Dual cameras | To ensure the accuracy of the system, two cameras, a pick-up camera, and a dispensing camera, are used to monitor the pick-up and dispensing status in real-time |

| 4 | Light guide arm | A set of optical path refraction system is formed by combining precision prism with machined parts to achieve high accuracy |

| 5 | FAC pick-up fixture | A clamping lens with an accompanying sensor is utilized to ensure the highest level of clamping accuracy |

| 6 | The power-on components | Real-time adjustments to the position of the chips are made using a manual displacement stage for precise alignment |

| 7 | X axis | Travel: 300mm Resolution: {Full/Half: 2μm/1μm, Microstep (1/20 Microstepping) 0.1μm} |

| 8 | Y axis | Travel: 30mm Resolution: {Full/Half: 2μm/1μm, Microstep (1/20 Microstepping) 0.1μm} |

| 9 | Z axis | Travel: 50mm Resolution: {Full/Half: 2μm/1μm, Microstep (1/20 Microstepping) 0.1μm} |

| 10 | CX axis | Travel: 200mm Resolution: {Full/Half: 2μm/1μm, Microstep (1/20 Microstepping) 0.1μm} |

| 11 | CY axis | Travel: 20mm Resolution: {Full: 0.2μm, Half: 0.1μm} |

| 12 | CZ axis | Travel: 100mm Resolution: {Full: 2μm, Half: 1μm} |

| 13 | θX (Pitch axis) | Travel: ±4°, Repeated positioning accuracy: ±0.001° |

| 14 | θY (Yaw axis) | Travel: ±8°, Repeated Positioning accuracy: within ±0.005° |

| 15 | θZ (Roll axis) | Travel: ±4°, Repeated positioning accuracy: ±0.001° |